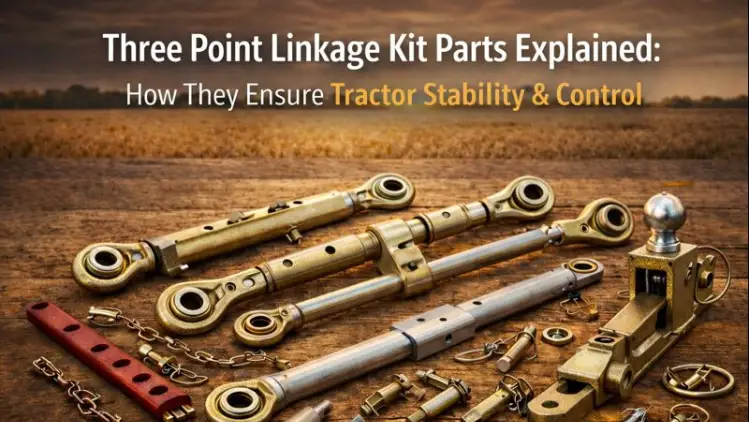

Tractor stability is not defined by engine power or tractor weight alone. In real farming conditions, stability depends on how efficiently the tractor transfers power to the implement, how evenly the load is distributed, and how well unwanted movement is controlled. At the centre of this entire mechanism is the three-point linkage system.

Most instability-related issues—such as excessive side sway, uneven working depth, jerky lifting, or sudden implement drop—can be traced back to worn, mismatched, or poorly maintained linkage components. This guide explains three point linkage kit parts in detail, focusing on how each component contributes to tractor stability, operator safety, and consistent field performance.

Understanding the Three Point Linkage System

The three-point linkage system connects implements to the tractor using three mounting points: two lower links and one top link. This triangular geometry is not accidental—it is designed to distribute load evenly between the tractor’s rear axle and chassis while allowing controlled vertical and horizontal movement.

When the linkage system is working correctly, it allows the tractor to:

- Lift heavy implements smoothly without jerks

- Maintain a consistent working depth across the field

- Transfer draft forces efficiently to the rear wheels

- Reduce stress on hydraulic and structural components

A complete set of Three Point Linkage Kit Parts functions as a single system. Even if one part develops excessive play or weakness, the entire system’s stability is compromised.

Why Tractor Stability Depends on Linkage Quality

In day-to-day operations, instability rarely appears suddenly. It develops gradually and is often ignored until it becomes dangerous or costly. Common early symptoms include the implement drifting sideways, inconsistent depth, excessive vibration, or frequent need for operator correction.

These issues occur because worn linkage parts fail to hold the implement in a fixed geometric relationship with the tractor. As a result:

- Load transfer becomes uneven

- Tractor balance shifts unpredictably

- Hydraulic components face shock loads

- Tyres lose consistent traction

Replacing linkage parts proactively prevents secondary damage to hydraulics, tyres, and transmission systems, while also reducing operator fatigue.

Top Link Assemblies: Controlling Implement Angle and Load Transfer

The top link is responsible for controlling the fore-and-aft angle of the implement. This angle directly affects how the implement penetrates the soil and how draft force is transferred back to the tractor.

High-quality Top Link Assemblies allow precise adjustment and maintain rigidity under load.

When top links are worn or mismatched:

- The implement may dig too aggressively or ride too shallow

- Sudden bouncing can occur during operation

- Load shifts unevenly to the lower links

- Tractor front-end balance may be affected

From an experienced operator’s perspective, even a small amount of play in the top link can significantly affect stability, especially during heavy tillage or uneven terrain.

Levelling Assemblies: Ensuring Uniform Working Depth

Levelling assemblies ensure that both lower links remain at equal height, keeping the implement level relative to the ground. This is critical for operations where uniform depth directly affects output quality, such as tillage or seeding.

Durable Levelling Assemblies maintain alignment under continuous load and vibration.

Worn levelling assemblies often lead to:

- One side of the implement working deeper than the other

- Uneven soil structure across the field

- Increased drag on one tractor wheel

- Higher fuel consumption due to imbalance

Proper levelling improves field consistency, reduces corrective steering, and minimizes unnecessary stress on the tractor.

Stabilizer Assemblies: Controlling Side Sway and Improving Safety

Side sway is one of the most underestimated safety risks in tractor operations. When stabilizers are loose or worn, the implement can swing laterally, especially during turns or transport.

Well-designed Stabilizer Assemblies limit this unwanted movement without restricting necessary vertical motion.

Effective stabilizers:

- Keep the implement aligned behind the tractor

- Prevent sudden side movement on uneven ground

- Reduce impact loads on linkage joints

- Improve control during road transport

Ignoring stabilizer wear often results in accelerated pin and bush damage, eventually leading to unsafe operating conditions.

Draw Bars: Managing Draft Loads and Towing Stability

Draw bars are used when implements or trailers require pulling force rather than lifting. In such cases, the point at which force is applied becomes extremely important for tractor balance.

Correctly engineered Draw Bars ensure that towing forces are applied at a safe height and angle.

Improper draw bar selection or positioning can cause:

- Reduced steering control due to front-end lightening

- Excessive rear lift under load

- Increased risk of rear overturn

- Uneven stress on tractor frame and linkage

Using the correct draw bar is a key safety requirement, not just a convenience.

Levelling Arms: Fine Adjustment for Implement Balance

Levelling arms work in combination with levelling assemblies to provide precise height adjustment on either side of the implement. While levelling assemblies manage gross alignment, levelling arms allow operators to fine-tune balance based on field conditions.

High-strength Levelling Arms are especially important during operations where even slight depth variation can affect output quality, such as seeding or shallow tillage.

Worn or bent levelling arms often result in:

- Frequent readjustment during work

- Uneven soil finish

- Increased operator fatigue

U-Bolts: Structural Clamping and Load Retention

U-bolts are used to clamp linkage components securely to tractor frames or brackets. Though they do not move during operation, their role is critical in maintaining structural integrity under load.

Properly rated U-Bolts ensure that linkage components remain firmly positioned even under vibration and shock loads.

Loose or low-grade U-bolts can lead to:

- Gradual misalignment of linkage geometry

- Uneven stress distribution

- Sudden failure during heavy draft work

Top Link Ends and Weld-On Ends: Restoring Worn Linkage Assemblies

Top link ends and weld-on ends are commonly used when the main linkage rod is still structurally sound but the threaded or joint ends have worn out.

- Top Link Ends allow quick restoration without replacing the full assembly

- Weld On Ends are used in custom or heavy-duty repair applications

From a professional maintenance standpoint, replacing ends instead of the entire assembly:

- Reduces downtime

- Lowers repair cost

- Extends linkage life

Stabilizer Ends: Maintaining Controlled Lateral Movement

Stabilizer ends connect stabilizer assemblies to the linkage arms and absorb side loads during operation.

Durable Stabilizer Ends ensure that stabilizers function correctly without excessive play.

Worn stabilizer ends are a common cause of:

- Side sway returning even after stabilizer adjustment

- Increased pin and bush wear

- Reduced effectiveness of the stabilizer system

Balls: Enabling Smooth Articulation Under Load

Linkage balls are used at joint points to allow controlled rotation and articulation while transferring heavy loads.

Precision-machined Linkage Balls:

- Reduce friction

- Allow smooth joint movement

- Prevent binding under load

Excessively worn balls often cause jerky lifting and uneven implement response.

Pins: Small Components That Determine System Integrity

Pins are often the first components to fail because they experience continuous shear, vibration, and load reversal. Despite their size, they are among the most critical linkage parts.

A complete range of Three Point Linkage Pins is used to secure different connections.

- Top and Lower Link Pins handle primary load transfer and must fit precisely to avoid play.

- Hitch Pins allow quick attachment but must still maintain tight tolerances.

- PTO Pins secure rotating components and must resist vibration.

- Clevis Pins are used in pivoting joints and require smooth surface finish.

- Hair, Split, and Grip Pins provide secondary locking and prevent accidental disengagement.

- Implement Pins are designed for heavy-duty implement attachment under high load.

Professional operators replace pins as soon as wear-induced play appears, preventing damage to expensive linkage arms and brackets.

Bushes: Preserving Alignment and Reducing Wear

Bushes act as sacrificial wear components between moving parts. Their role is to absorb friction and maintain alignment.

When bushes wear out:

- Pins begin to move excessively

- Vibration increases

- Metal-to-metal contact accelerates damage

- Overall linkage accuracy declines

Timely bush replacement restores tight tolerances and significantly extends the life of the entire linkage system.

How to Choose the Right Three Point Linkage Kit Parts

Experienced professionals follow a structured approach:

- Match tractor category and load rating exactly

- Select hardened, wear-resistant materials

- Ensure dimensional accuracy and proper fit

- Replace related components together

This approach reduces repeat failures and ensures long-term stability.

Conclusion

Three point linkage kit parts are the foundation of tractor stability, safety, and efficient implement control. Each component—from top links and levelling assemblies to stabilizers, draw bars, pins, and bushes—plays a specific and irreplaceable role in maintaining balance under real field conditions.

Investing in high-quality linkage components and replacing them proactively ensures safer operations, protects tractor systems, and delivers consistent performance season after season.

Frequently Asked Questions (FAQs)

Three point linkage kit parts are components that connect farm implements to a tractor for lifting, lowering, and depth control. These parts typically include top links, levelling assemblies, stabilizers, draw bars, linkage pins, and bushes, all of which work together to maintain tractor balance and controlled implements movement.

Three point linkage kit parts improve tractor stability by evenly distributing implement load between the tractor’s rear axle and chassis. Properly adjusted linkage components reduce side sway, limit excessive vibration, and maintain consistent working depth, especially when operating on uneven or sloped fields.

Key three point linkage kit parts for safe operation include top links for angle control, stabilizers for preventing sideways movement, levelling assemblies for uniform depth, and high-strength pins and bushes for secure attachment. Worn or loose parts can cause sudden implement movement and increase safety risks.

Worn three point linkage kit parts can lead to uneven implement depth, excessive sway, increased vibration, poor load control, and sudden implement drop. These issues not only reduce work quality but also increase the risk of tractor imbalance, operator fatigue, and mechanical failure.

Three point linkage kit parts should be inspected regularly, especially before heavy field operations such as ploughing or harvesting. Replacement is recommended when signs of wear, elongation of pin holes, looseness, or reduced load control appear, as timely replacement helps maintain tractor stability and safe operation.